Trusted company that deals in quality-made products

- PUF Panels

- Insulated Roof Panels

- Porta Cabins

- Prefab Shelters

- Bunk Houses

- Cold Storage Room

- Labour Huts

- Double Storey Building

- Cold Room Storage Doors

- Operating Theatre Room

- Insulated Panels

- Prefabricated Buildings

- Sandwich Panels

- Walk In Freezer

- Roofing Sheet

- Prefabricated House

- Portable Cabin

- Prefabricated Structure

- Puf Sandwich Panel

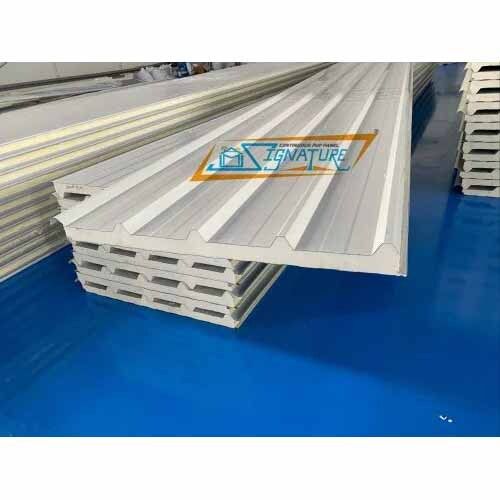

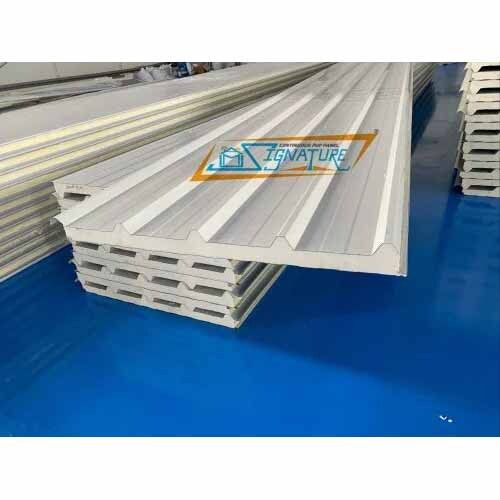

Insulated Roofing Panels

1000 INR/Square Meter

Product Details:

- Type Metal Insulated Roof Panels

- Size Standard

- Shape Rectangular

- Pattern Color Coated, Galvanised, Coated

- Thickness 30MM TO 120MM Millimeter (mm)

- Click to View more

X

Insulated Roofing Panels Price And Quantity

- 500 Square Meter

- 1000 INR/Square Meter

Insulated Roofing Panels Product Specifications

- Standard

- Color Coated, Galvanised, Coated

- Rectangular

- 30MM TO 120MM Millimeter (mm)

- Metal Insulated Roof Panels

Insulated Roofing Panels Trade Information

- 5000 Square Meter Per Month

- 7 Days

Product Description

Metal insulated roof panels are a great insulation and are strong enough to withstand the heat of a building. Panels are made up of a core of high density polyurethane foam sandwiched between two layers of high-quality metal sheets, usually steel or aluminum. Thermal efficiency is amazing, it minimizes heat transfer and keeps you warm inside all year long.

Metal insulated roof panels with polyurethane foam core are cost effective and can save you money on heating and cooling This helps in sustainability initiatives by reducing carbon emissions and encouraging energy efficient construction.

Lightweight and sturdy, these roof panels can be easily handled, transported and installed on site. Their robustness guarantees against weather conditions, fire, and corrosion, ensuring long lasting durability with minimal upkeep.

Metal insulated roof panels are available in a range of thicknesses, profiles, and finishes, which are well suited for a variety of architectural applications such as industrial buildings, warehouses, commercial complexes, residential homes. Quick installation is a cost effective option for contemporary roofing solutions that prioritize energy efficiency and environmental sustainability, as well as reducing labor costs and accelerating construction time.

FAQ of Metal Insulated Roof Panels?

Q.What are metal insulated roof panels?

A.Metal insulated roof panels consist of a core of rigid insulation material, typically polyurethane foam, sandwiched between two metal sheets, usually made of steel or aluminum. They provide excellent thermal and acoustic insulation.

Q. What are the key benefits of metal insulated roof panels?

A. Metal insulated roof panels are durable, lightweight, easy to install, and help improve energy efficiency by reducing heating and cooling costs. They are also fire-resistant and weather-proof.

Q. What are the typical dimensions of metal insulated roof panels?

A.Standard metal insulated roof panels have widths ranging from 1000-1700 mm, lengths from 1200-6000 mm, and thicknesses from 50-200 mm, with 1000 mm width and custom lengths being most common.

Q. How are metal insulated roof panels installed?

A. Metal insulated roof panels are installed by first fixing appropriate brackets to the roof structure using mechanical fasteners. The panels are then interlocked together and sealed with butyl tape and flashings to create an airtight and watertight joint.

Q. What are some common applications of metal insulated roof panels?

A. Metal insulated roof panels are widely used in industrial buildings, warehouses, commercial facilities, cold storage units, and prefabricated structures due to their insulating properties, durability, and ease of installation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Insulated Panels' category

We mainly deal in Gujarat, Maharashtra, Rajasthan and Madhya Pradesh.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free